Alka Raman

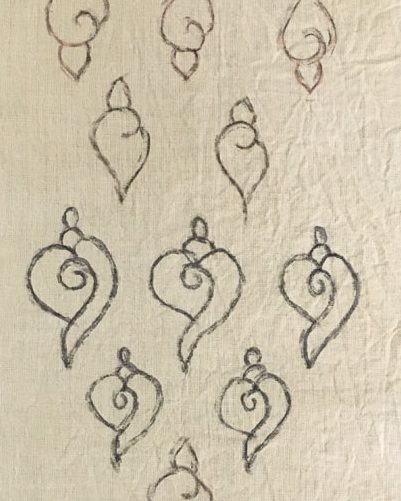

Sample 1: Drawing with Alum and Iron Mordants

This sample shows the cloth at one of the earliest stages of chintz making. The cloth underwent preparations involving scouring, myrobalan soak and boil, as well as a myrobalan and milk soak. Designs were then outlined on the cloth with a charcoal pencil. All conch 1 shapes (top five and bottom one) are outlined in a liquor made of alum and sappanwood, where red or its variations are required. All conch 2 shapes are outlined in a mixture of iron water and acid congee (fermented rice water) where a black outline is required.

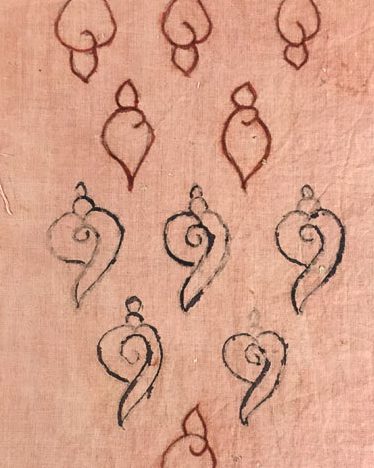

Sample 2: First Maddering

After the outlining of the designs with the alum and iron mordants, the cloth underwent its first madder bath. It was immersed in a bath made of powdered madder root and water, and brought up to heat in the bath, with temperature maintained under 60°C, for 2 hours. This cloth shows the vivid outlines in red and black after the process of the first “maddering.”

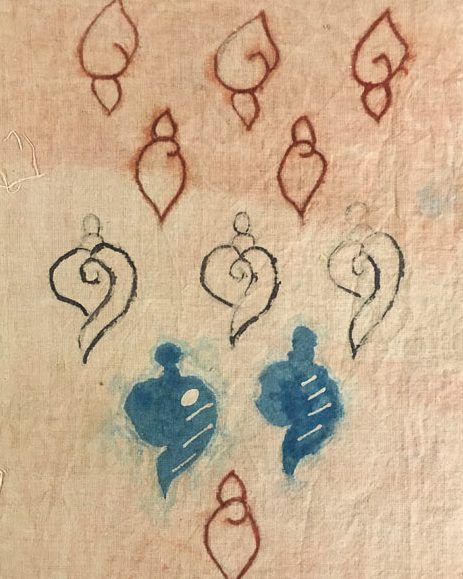

Sample 3: First Dunging and Bleaching

This sample shows the cloth after its first dunging-plus-bleaching. The cloth will undergo four dungings and bleachings in all during the process of chintz making. In the absence of kid-dung, which was recommended by the Beaulieu manuscript for dunging, a modern version of soaking cloth in a mixture of wheat bran and chalk (calcium carbonate) mixed with warm water, was adopted. For bleaching, the cloth was dried under full spectrum sun lamps to imitate sunlight.

Sample 4: Wax as Resist

Following the first round of dunging-bleaching, rice starch was applied to the cloth. Once the starched cloth was dry, it was ready for wax as a resist, to prevent indigo from going into parts of the cloth where it was not required. This sample shows wax applied to the outlines of specific designs where blue was required within the shape, as well as to parts where inside the shape certain areas needed to remain free of the blue.

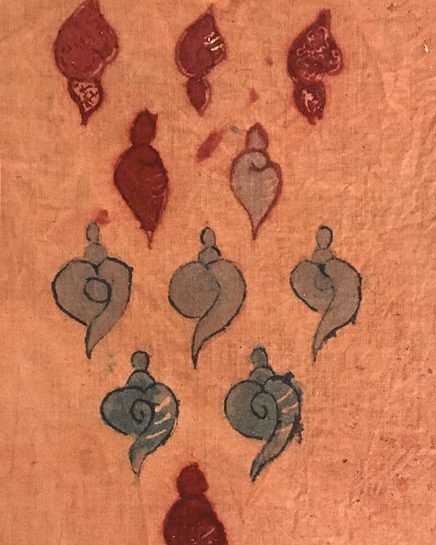

Sample 5: Vatting-Direct Indigo Application

The Beaulieu manuscript refers to both vatting as well as direct application of indigo to the cloth at this stage. This sample illustrates only direct application of indigo, to demonstrate that not only is it possible, but it also remains an effective and efficient method of indigo application. This sample shows the indigo directly applied with the aid of soy wax as resist, the cloth scraped in hot water to remove the wax, and the cloth having gone through its second dunging-bleaching following the removal of the wax.

Sample 6: Streaking

White, red, blue/green, yellow/orange, brown/violet

At this stage, Beaulieu witnessed the Indian artisan applying colors in a series of steps to achieve variations of white, red, blue, green, yellow, brown, and violet on the cloth. Blue and yellow are clearly visible on the cloth at this stage, violet and brown less so, though they are yet to go through the next round of maddering to solidify the colors.

Sample 7: Second Maddering

This is what the sample looks like after the second round of concentrated maddering for four hours. The cloth has taken on a very dark red color over the background, indicating that the quantities of madder were likely too high in the bath. Equally, the overwhelming red within the designs where yellow, orange, brown, and orange were to be visible indicates issues with the measurements of the liquors used to achieve these colors on the cloth. Given the unclear measurements within the Beaulieu manuscript, it would have been a long process of empirical trial and error to arrive at the right measurements resulting in the right colors on cloth.

Sample 8: Stain Removal, Dunging, and Washing

This sample has undergone a special natural stain removal as suggested in the manuscript—scrubbing with pieces of lime. Where the scrubbing has been efficient, there the background of the cloth is clearer. Following the stain removal, the cloth was washed in a solution of soap berries. While some of the madder attached to the background has come off, the cloth remains overwhelmingly red, indicating too much madder in the second bath.

Sample 9: Final Yellow/Green

This sample has only one motif (conch 2b) covered in a mixture of cadouca-myrobalan-madder applied on blue to allow for the development of green. The motif shows negligible traces of yellow on blue, indicating another instance of trouble with measurements. This sample has also undergone the final dunging-sanding-soaping, which removed any residues of loosely attached cadouca-myrobalan-madder to the motif.

Sample 10: The Final Cloth

Following the instructions in the Beaulieu manuscript as closely as possible and making reasonable adjustments, as far as possible, without using insights available through modern techniques of natural dyeing, the final sample shows red, black, blue, brown/violet and techniques that would have illustrated white, green, yellow, and orange in the hands of a more experienced and skilled artisan.

Conclusions

The transfer of cotton printing-painting knowledge from India to Europe exhibits a case of partially useful knowledge requiring adjustments and adaptations in line with local European conditions. Certain variable elements, like deciphering the exact measurements of materials to obtain required results, would have been achievable through prolonged trial and error, as well as empirical investigations. However, certain fixed elements required by the process, like ample sunlight as part of the process of bleaching, or the use of chay root, which was unavailable in Europe, acted as fixed and largely unsurmountable constraints in Europe. Two of the earliest innovations in textile printing in Europe were aimed at overcoming these fixed constraints via the development of chemical bleaching and the isolation of alizarin for the color red.

Glossary

Myrobalan: A fruit-bearing plant that produces a buff to brown color dye or a teal color if overdyed with indigo

Madder: A plant used to create a red dye

Alum: A binder used to fix dyes

Sappanwood: A flowering tree used to create red dye

Congee: Rice porridge

Mordant: Dye fixatives used to set dyes in fabric

Dunging: traditional process using cow dung to fix or remove mordants

Note on the Process

Charting Chintz attempts to be as close to the chintz-making process described in the Beaulieu manuscript as possible, only using technique or product substitutions where either products were unavailable or technique not possible in its described form, or both. Key substitutions made are as follows:

- Initial scouring (recipe unknown) substituted with synthrapol and soda ash

- Chay root substituted with madder root

- Dunging using kid dung substituted with dunging with wheat bran and chalk

- Beeswax for resisting (recipe unknown) substituted with soy wax

- Sunlight substituted with full spectrum sun lamp